Type:

Robot cell with one single robot.

Sector:

Biomedical.

Function:

Grinding and polishing titanium surgical implants.

Details:

Robotic cell with a single robot for processing titanium prosthesis.

The machine includes an ABB robot, CANopen connected variable speed drives and a PLC connected to the robot via DEVICENET.

The robot trajectories are very complex because they have to follow the shape of the piece at constant speed while maintaining constant pressure against the work tools while avoiding heating the material.

Type:

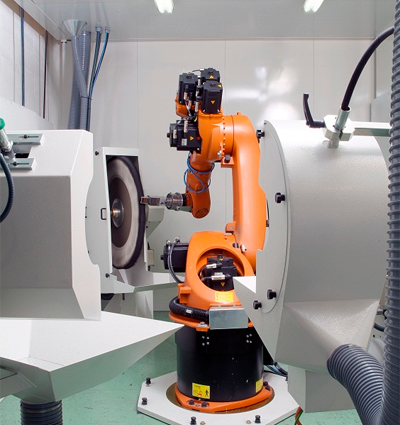

Robot cell with one single robot.

Sector:

Luxury audio.

Function:

Luxury audio parts polishing.

Details:

Single robot robotic cell for polishing luxury audio system components.

The machine includes a KUKA robot, servomotors and servoamplifiers connected via EtherCAT, CANopen connected variable speed drives, connection to the PLC control via DEVICENET.

The robot trajectories are very complex because they have to follow the shape of the piece at constant speed while maintaining constant pressure against the working tools.

Type:

Robot cell with two robots working together.

Sector:

Automotive

Function:

Grind and polish automotive parts.

Details:

Robotic cell with two robots working together to grind parts for the automotive sector.

The machine includes two ABB robots, variable speed drives connected via CANOpen, PLC connected via DEVICENET.

Is guaranteed at all times that the two robots that act in common areas will not collide.

Type:

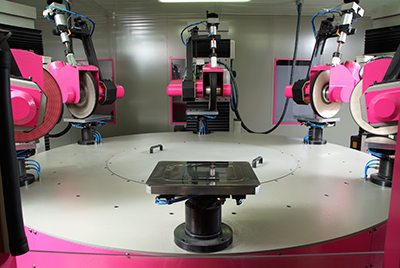

Robot cell with four robots working together.

Sector:

Sanitary fittings.

Function:

Grind and polish sanitary fittings.

Details:

Robotic cell with four robots working in a special provision for grinding and polishing faucets.

The machine includes four ABB robots, PLC connected via DEVICENET.

The robots are calibrated to get identical processes while programming only one robot.

Type:

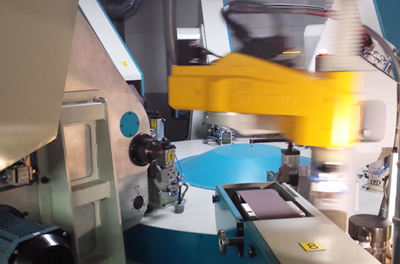

Machine with 26 CNC axis and multiple interpolation channels.

Sector:

Gift jewelry.

Function:

Polishing gift photo-frames and jewelry.

Details:

CNC machine with 26 axes, 5 interpolation channels and interpolation group changes at runtime.

The machine includes 26 servomotors and servoamplifiers connected via EtherCAT, CANopen connected frequency inverters, distributed periphery, PC based control, SoftCNC and SoftPLC.

Safety PLC.

Type:

Machine with 12 CNC axes, multiple interpolation channels and a SCARA robot.

Sector:

General industry.

Function:

Grinding aluminum parts.

Details:

CNC machine with 12 axes, 6 interpolation channels, artificial vision and a Staubli SCARA robot for automatic loading.

The machine includes a Stäubli robot, servomotors and servoamplifiers connected via EtherCAT, PLC connected via EtherCAT.

Vision to correct the position of the robot grip.

Type:

Robot cell with two robots working together.

Sector:

Luxury audio.

Function:

Luxury audio parts polishing.

Details:

Robotic cell with two robots working together in trajectory synchronization.

The machine includes two KUKA robots, one cable technology (OCT) servomotor and servoamplifier connected via EtherCAT, PLC connected via EtherCAT.

A robot carries the piece and the other carries the tool to achieve the complexity of the trajectories.

| We work hard to excellence and do it for you |